Wearables, Week 1: Favorite Garment Tracking

I had a difficult time choosing my favorite garment. I don’t think much about my clothes (hence why most of them are black). I thought about doing an old shirt of my mom’s, but all of the evidence about where it came from has been rubbed away – though, to be fair I spent a lot of time today listening to the Planet Money podcasts about where a t-shirt comes from and learned a lot about cotton production, spinning yarn and Bangladeshi garment factories.

So I decided to go with my favorite pair of running tights, made by EMS. They’re long, black and keep me warm on my winter runs. As something more on the technical side, I wonder how it different form the t-shirt production narrative.

The garment is 86% nylon, 14% spandex. It’s from the Fall 2014 EMS line, style # F14W0291.

A description of EMS from their website:

“Founded in 1967 by two New England rock climbers and based in Peterborough, N.H., Eastern Mountain Sports is one of the nation’s leading outfitters of outdoor gear, clothing, footwear and accessories with 69 retail stores in 12 states. Eastern Mountain Sports designs and sells products for outdoor adventurers who participate in a variety of sports, such as mountaineering, backpacking, camping, hiking, adventure racing, climbing, kayaking, mountain biking and snow sports. More information is available at www.ems.com.” There isn’t any information about manufacturing on their website and external searches yield more information about business and merchandising than the EMS brand of clothing they sell in store.

I did a search on the garment industry in El Salvador. It looks like most clothing is manufactured in Asia because of cheaper costs, but that nation-states have banded together to protect their industries. El Salvador does both yarn, fabric and apparel production. Apparently is known for their production of synthetic fabrics such as the ones used in this garment. From a website about textile production in El Salvador:

El Salvador… since 2004, the country has been working on executing a strategy that has allowed the country’s textile and apparel industry to develop structural changes in factories and mills by engagement in capacity-building programs and by meeting international compliance and standards in labor and environmental regulations.

The goal was to develop virtual and vertical companies for both replenishment of commodity businesses and the development of niche products that promoted a strategic relationship between textile mills, garment factories and retailers that would reduce costs, increase efficiency and flexibility allowing El Salvador to take advantage of our geographic proximity to the United States. One of the results of executing this strategy was the establishment of a robust and vertically integrated synthetic-textile manufacturing cluster that has developed over the past several years. This synthetics cluster includes polyester and nylon yarn, narrow elastics, circular and warp-knit stretch fabrics and apparel manufacturers for markets such as athletic wear, sportswear, performance wear and swimwear.

source: http://www.tradegood.com/de/viewpoints/apparel-made-in-el-salvador.html

Apparently to give themselves an edge, El Salvador has been working on new technologies and pushing production of synthetics.

BWA is an example of a manufacturer of performance apparel. For BWA, textiles are designed in Portugal and employs highly technologically trained employees. They have strong mill partnerships in Europe, China, South Korea, and Taiwan.

According to wikipedia, artificial fibers are produced by extruding a polymer, through a spinneret into a medium where it hardens. Nylons involved melt spinning, where the extruded polymer is cooled in gas or air and then sets. After listening to the planet money episode, it’s interesting to see the contrast between manufacturing natural fibers vs artificial. Apparently spandex was original invented to replace rubber (http://www.madehow.com/Volume-4/Spandex.html). DuPont was involved in creating nylon, and combined spandex threads with nylon to make it more pliable.

On how spandex is made:

Two types of prepolymers are reacted to produce the spandex fiber polymer back-bone. One is a flexible macroglycol while the other is a stiff diisocyanate. The macro-glycol can be a polyester, polyether, polycarbonate, polycaprolactone or some combination of these. These are long chain polymers, which have hydroxyl groups (-OH) on both ends. The important feature of these molecules is that they are long and flexible. This part of the spandex fiber is responsible for its stretching characteristic. The other prepolymer used to produce spandex is a polymeric diisocyanate. This is a shorter chain polymer, which has an isocyanate (-NCO) group on both ends. The principal characteristic of this molecule is its rigidity. In the fiber, this molecule provides strength.

Read more: http://www.madehow.com/Volume-4/Spandex.html#ixzz3ytLxkRoz

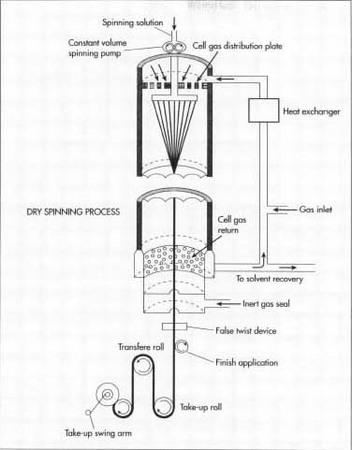

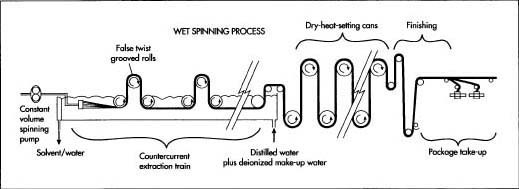

The production process involves melt extrusion, reaction spinning, solution dry spinning, and solution wet spinning.

dry spinning process

wet spinning process

I also learned that the name spandex is an anagram of expands. Clever inventors.

Honestly, from looking into this garment it seems that the industry is quite secretive. It was almost impossible to find anything specific from EMS and even though looking at similar types of manufacturers like REI, a company known for their transparency and commitment to social values. It makes me curious as to how people go about sourcing materials and workshops to produce their pieces.